Innovate for

your performance

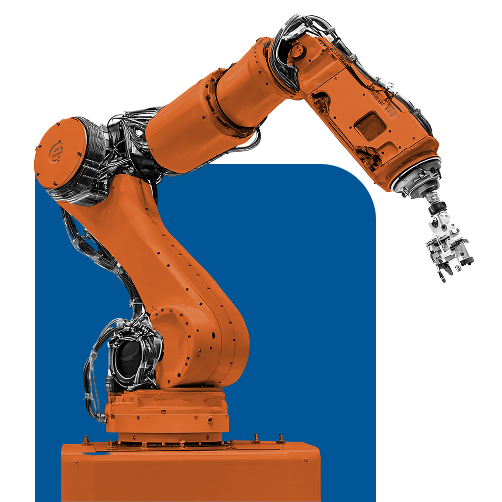

Robotic installations

You need to…

- Automate tasks to improve productivity and reduce costs

- Optimize precision for processes such as welding, assembly, or handling

- Reduce human error in complex production lines

- Improve operator safety with robotic solutions that handle potentially hazardous tasks

- Adapt to specific spaces and constraints: customers are looking for custom-designed robotic cells to integrate with their existing infrastructure

- Have a turnkey solution, from design to commissioning, including operator training

...FARMAN meets your needs and offers you:

- Specialized robotic cells

- Handling

Robots adapted to move, sort, or transport parts of varying weight - Welding

Robotic solutions to ensure consistent and precise welds - Assembly

Robotic cells for precise, fast, and reliable assembly

- Tools for robotic cells

Custom design to meet specific handling, fixation and repeatability needs

Key process :

1 Analysis of your needs

In-depth study of the client’s constraints and objectives

2 Conception

Development of a personalized solution, integrating the latest robotic technologies

3 Manufacturing and integration

Cell development and on-site installation

4 Validation and training

Testing to ensure compliance and performance, with team training for optimal use

5Maintenance and monitoring

Technical support and preventive maintenance to maximize equipment lifespan

…The + FARMAN for your robotic installations

- Total customization

Customized solutions to meet the specific needs of each client

- Expertise

Expertise in the integration of robotic installations

- Complete support

From feasibility study to implementation, with responsive technical support

- Cutting-edge technology

Using the best tools and equipment to ensure performance and reliability.

- Quality commitment

Certifications and compliance with international standards for compliant and sustainable solutions

They trust us

In search of a solution tailored to your industrial challenges?

Contact us now to discuss your project and discover how our robotic solutions can transform your production!

Accumulation conveyors

You need to …

- Optimizing production flows: the need for efficient systems to transport parts or products in workshops or production lines

- Managing space constraints: the need to adapt conveyors to complex and/or restricted environments

- Reducing downtime and slowdowns in industrial processes

- Securing the transport of parts to avoid loss or damage

- Simplifying maintenance: the need for modular solutions with easy-to-replace spare parts to limit production downtime

- Integrating with existing equipment: compatibility with existing machines and robots

...FARMAN meets your needs and offers you:

- Floor conveyors

Ideal for regular flows in standard spaces, with great robustness and precision necessary for a robotic environment

- Overhead conveyors

Suitable for restricted environments or those requiring floor space savings

- Triple conveyors

Allows the transport of larger and heavier parts for a smooth and automated process

- Spare parts

Rapid supply of components for the maintenance of existing systems with a dedicated Spare Parts service

Key process :

1 Analysis of your needs

Analysis of production flows and specific customer constraints

2 Conception

Creation of a detailed plan to choose the appropriate type of conveyor (ground, overhead, triple). Development of conveyors taking into account the specificities of the project

3 Manufacturing

Manufactured in our French factory with factory operational testing before sending to site

4 Installation and integration

On-site assembly and connection to existing equipment

5 Maintenance and monitoring

Monitoring and support to ensure the sustainability of systems

… The + FARMAN for your accumulation conveyors

- Versatility of solutions

Wide range of conveyors to meet various needs, whether standard or custom-made

- Modularity and scalability

Conveyors designed to be adjusted or improved according to future needs

- Reliability and robustness

High-quality materials guarantee a long service life

- Responsive after-sales service

Rapid availability of spare parts and fast, responsive technical support

- Compliance with international standards

Compliance with safety and industrial sustainability requirements

They trust us

In search of a conveyor solution tailored to your needs?

Contact us now to discuss your project and find out how to optimize your production workflows safely and efficiently!

Retrofit

You need to …

- Modernizing existing equipment: Clients want to extend the lifespan of their facilities without having to invest in costly new equipment.

- Compliance with current standards: Need to ensure that facilities meet current safety and environmental standards.

- Optimizing performance: Aging equipment loses efficiency, increasing downtime and reducing productivity.

- Integrating new technologies: Need to adapt existing facilities to take advantage of new innovations.

- Reducing costs: Seeking an economical alternative to purchasing new equipment while improving the performance of current systems.

- CSR approach: Need to integrate equipment into assembly lines that meets our clients’ CSR approach while respecting the environment.

...FARMAN meets your needs and offers you:

- Renovation of conveyors

Modernization of conveyor systems for better performance, including motorization and automated control

- Upgrading robotic installations

Addition or replacement of key components (motors, sensors, control systems) to improve accuracy and reliability

- Technological adaptation

Integration of new technologies (sensors, robots, modern interfaces) into existing systems

- Adaptation to a new production

Modification of existing robotic cells to adapt to the production of a new product

Key process:

1 Initial diagnosis

In-depth analysis of equipment to identify weaknesses, opportunities for improvement, and specific needs

2 Conception and planning

Proposal of a detailed retrofit plan, including necessary updates and expected benefits

3 Intervention

Carrying out renovation work, replacing parts, or reprogramming systems

4 Tests and validation

Verification of the conformity and performance of renovated equipment

5 Training and monitoring

Supporting teams in the use of modernized facilities and setting up post-renovation monitoring

… The + FARMAN for the retrofit of your equipment

- Multibrand expertise

Ability to work on equipment of all brands thanks to extensive experience and diverse know-how

- Cost effective solution

Lower cost than new equipment, with comparable performance

- Better durability

Extending the life of installations with environmentally friendly solutions

- Full customization

Solutions tailored to the specific needs of each client, taking into account technical and budgetary constraints

- Complete support

Diagnosis, intervention, monitoring, and maintenance to ensure customer satisfaction

They trust us

Modernize your equipment without investing in new equipment!

Contact us now to discover our retrofit and optimization solutions tailored to your needs!